Three cast off burning boiler and blown gas waste heat boiler are ideal equipment of high efficiency and energy-saving in fertilizer and chemical (esp. methanol, ethanol, formaldehyde, and synthetic ammonia) industry. According to the features of waste heat flue gas of this industry, the waste heat boiler developed by our company mainly can be divided in to two types of natural circulation waste heat boiler: vertical type and tunnel kiln horizontal type. This waste heat boiler is typical energy-efficient equipment in chemical circular economy; it can support the three castoff burning boiler and blown down gas waste heat boiler and help the production enterprise to completely realized the enterprise and thoroughly achieving the goal of safety, environmental protection, improving of output and efficiency , and energy saving.

Advantage Feature

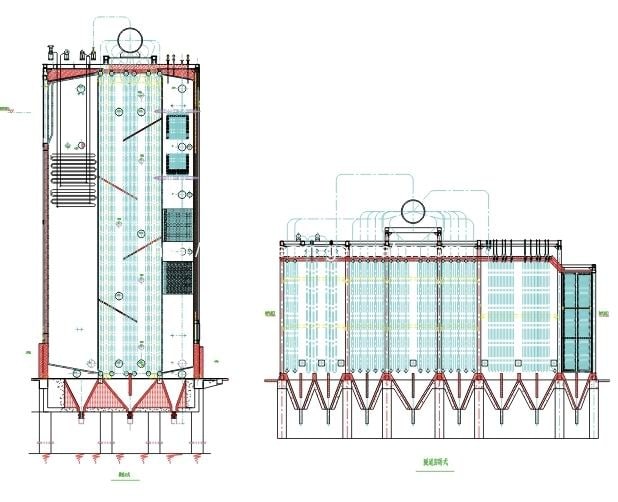

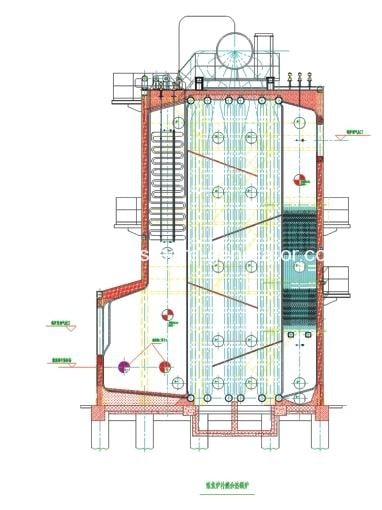

This type of waste heat boiler consists of main heating surfaces like water-cooling panel, super-heater, and convection tube-bank. Coal-saving machine and air pre-heater etc. they have the following

advantages:

-

The heating surface of the boiler employs suspension structure which is good for absorbing boiler expansion and is of high operation safety;

- The boiler used special sealing devices to reduce boiler air leakage and improve boiler efficiency;

-

The heating surface of boiler employs reasonable flue gas velocity design to prevent soot accumulation;

-

The boiler adopts straight-through arrangement which can use deadweight of soot to self-remove soot and keep the heating surface clean and improve the heat exchange efficiency of the boiler;

-

The boiler properly organized flue gas dynamical field to keep steady and uniform flow of flue gas and avoid deflection, applying sole wear-resisting structure to avoid boiler abrasion and

longer boiler lifetime at the same time; -

The boiler convection tube-bank employs assembled structure with short installation period and low costs. And the vertical waste heat boiler has the advantages of small floor area, little investment in construction, high heat exchange efficiency and strong soot self-cleaning capability and so on.

Specification

The main specifications are as following: rated steam output 15-75t/h, rated steam pressure 1.25-9.8Mpa.

Customized Service

According to customer’s waste heat type, Romiter Machinery can provide customized design for the waste heat recovery project and help factory save the largest cost. Customer should provide waste gas component analysis and heat recovery boiler requirement for us.

Company Profile

Romiter Group concentrating on supply high efficient and high intelligent boiler for customer. Main products include wood pellet hot water boilers, wood pellet steam boiler, wood pellet burner, coal fired thermal oil heater, diesel oil fired thermal oil heaters, biomass steam generator(wood dust, corncob, bagasse, rice husk, palm kernel shell), coal fired hot air generator, wood pellet hot air furnace, electric steam generator, coal fired steam generator, coal water slurry steam generator, diesel oil or gas steam generator, thermal oil steam generators, heat recovery steam generator (HRSG).