As a new-type acid fuel in the place of oil base, water coal slurry is a high-tech product developed after the world oil crisis, serving as a new member of the fuel family. Water coal slurry is manufactured by means of coal, rich in reserve and moderate in price, as the major material after being ground and refined in addition of 27%~35% water and 1% chemical additive and etc.. It enjoys liquidity as good as and can be pumped, atomized and combusted as well as petroleum. With the calorific value equal to half of that of petroleum, its burn-up rate is raised from 60% of crude coal up to 90%, far higher than coal. Water coal slurry enjoys many advantages such as high combustion, good liquidity, facilitation of transportation, good storability and safety in use, etc., which can be widely used in industrial boiler, civilian boiler, thermal media furnace and power-station boiler. Falling in the national development program, water coal slurry would have a very promising market in the future.

- Heat Support:1800~35000kW

- Technical Features:

- Energy efficient design concept

- Optimal Design of the structure of thecombustion chamber

- Optimal Design technology of heat intensityof space

- More radiation paragraph structure

- Large radiating heat-absorbing technology

- Enhanced convection heat transfertechnology

- Automatic cleaning and multi-directionalcleaning technology

- Gas temperature control technology of mouthand throat furnace outlet

- Auto reset technology of explosion-proofdoors

- Optimal configuration system technology

- Complementary multi-stage dust removaltechnology

- Highly automated combustion controltechnology

- Dust and desulfurization removal technology

- Waste- heat recovery and otherenvironmental control technology

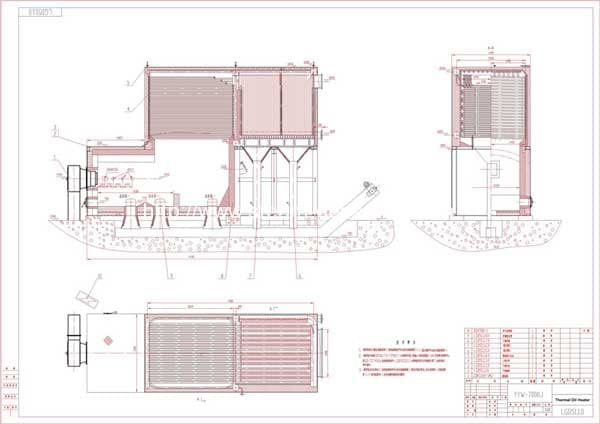

Coal Water Slurry Thermal Oil Heaters

Parameter Table of Coal Water Slurry Thermal Oil Heaters

| Model | YGL-1800A | YGL-3000A | YGL-4600A | YGL-70000A | YGL-14000A |

| Power | 1800(160) | 3000(250) | 4600(400) | 7000(600) | 14000(1200) |

| Thermal Efficiency | 78 | 78 | 78 | 78 | 80 |

| Rated Pressure | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Fuel Consumption | 426~450 | 710~750 | 1090~1150 | 1700~1800 | 3450~3600 |

| Heating Surface | 24/76 | 42/133 | 67/232 | 125/315 | 213/660 |

| Rated Working Temperature | 340 | 340 | 340 | 320 | 320 |

| Oil Circulating Volume | 100 | 160 | 260 | 400 | 635 |

| Outline Dimension(L*W*H) | 7.0*2.7*4.5 | 7.8*2.9*5.3 | 9.3*3.2*6.5 | 10*3.5*6.5 | 17.6*5.3*8.6 |

| Weight(t) | 35 | 48 | 75 | 103 | 190 |

| Transportation Weight(t) | 22 | 30 | 45 | 60 | 30 |

| Transportation Dimension(L*W*H) | 6.8*2.7*2.2 | 7.7*2.9*2.5 | 8.3*3.2*2.8 | 9.1*3.5*3.0 | 13.7*4.6*3.8 |

Thermal Oil Heaters Factory Visit

Workshope internal visit

Company Profile

Romiter Group concentrating on supply high efficient and high intelligent boiler for customer. Main products include wood pellet hot water boilers, wood pellet steam boiler, wood pellet burner, coal fired thermal oil heater, diesel oil fired thermal oil heaters, biomass steam generator(wood dust, corncob, bagasse, rice husk, palm kernel shell), coal fired hot air generator, wood pellet hot air furnace, electric steam generator, coal fired steam generator, coal water slurry steam generator, diesel oil or gas steam generator, thermal oil steam generators, heat recovery steam generator (HRSG).