The boiler of this industry includes two series of natural circulation water-tube waste heat boilers:

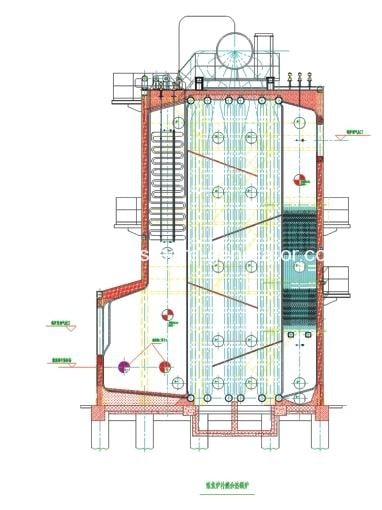

Carbon rotary kiln waste heat boiler and tank carbon waste heat boiler. with vertical II structure, the structure of the boilers is brand new and has advanced properties. It is original throughout China and is new-type carbon rotary kiln waste heat boiler developed

independently by this company.

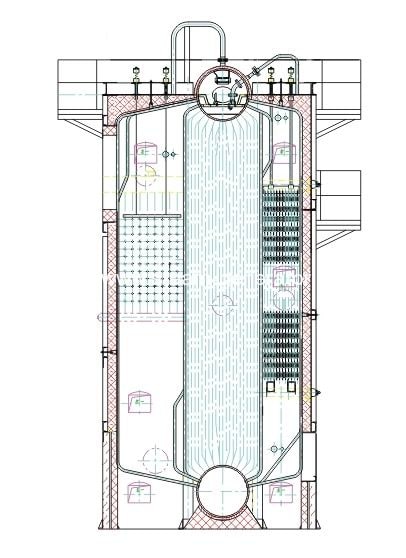

The flue gas is discharged from the boiler through boiler slag screen, super heater, convection tube tank and steel tube economizer. The boiler slag screen of boiler is lengthened structure, constituted by high temperature section and low temperature section, and face-type temperature reduction arrangement is adopted. The convection tube

tank is in-line pitching. Flue gas twice baffle plate is adopted to enhance the flue gas speed and form horizontal scouring, so the heat transfer capacity of convection tube tank is improved. Economizer employs S-shaped tube, and has horizontal scouring staggered arrangement. The central part of water-cooling system is membrane-type water wall separating wall; in this way, not only the heating surface is back water wall also adopts membrane-type water wall.

This boiler structure, compared with traditional carbon rotary kiln waste heat boiler, covers a smaller area, needs less investment is brand new and has advanced properties. It is of leading level in China and is new milestone in the development of carbon rotary kiln

waste heat boiler.

Specification

The main specification s are as following: rated steam output 2-130t/h, rated steam pressure 0.6-9.8Mpa.

Customized Service

According to customer’s waste heat type, Romiter Machinery can provide customized design for the waste heat recovery project and help factory save the largest cost. Customer should provide waste gas component analysis and heat recovery boiler requirement for us.

Company Profile

Romiter Group concentrating on supply high efficient and high intelligent boiler for customer. Main products include wood pellet hot water boilers, wood pellet steam boiler, wood pellet burner, coal fired thermal oil heater, diesel oil fired thermal oil heaters, biomass steam generator(wood dust, corncob, bagasse, rice husk, palm kernel shell), coal fired hot air generator, wood pellet hot air furnace, electric steam generator, coal fired steam generator, coal water slurry steam generator, diesel oil or gas steam generator, thermal oil steam generators, heat recovery steam generator (HRSG).