WNS-type oil (gas) boiler is a horizontal internal combustion three pass fire tube boilers. Furnace with bias wet back structure, high temperature gas erosion followed by the second and third return pipe, and then, after smoke from the room through the chimney into the atmosphere. Boilers fitted with smoke before and after the lid, so that the boiler easy maintenance. Boilers with excellent technical performance of the industrial burner, uses a combustion automatic ratio adjustment, automatic regulation, procedure start and stop, automatic operation and other advanced technologies, and has low water level alarm and low water levels, high vapor pressure, such as auto-flameout protection. This type of boiler with a compact, safe, reliable, simple, quick to install, less pollution, low noise, high efficiency.

WNS series oil / gas steam boiler protection:

- the water level real-time monitoring: detecting the water level with electronic devices, real-time monitoring boiler water level.

- time setting function: Users may need to set free combination boiler start and stop time.

- leakage protection: control system to detect leakage electric heating elements, it will automatically cut off power supply.

- water conservation: When the boiler when water is promptly cut off the burner control circuit, dry place to prevent damage to the burner, also issued a water shortage alarm controller direction.

- power protection function exception: the boiler stop running.

- interlocking overpressure protection: boiler pressure more than the user set value, the prohibition of burners work and alarm.

- pressure controller, water level alarm, safety valve, low water level of the multiple security alarm.

- the complete gas valve and protection system: providing from the filter, regulator, gas valve solenoid valves and accessories such as integrity, to ensure the safety of gas.

- gas monitoring device that can automatically monitor the boiler exhaust gas temperature, the more easily grasp the combustion boiler.

Parameter Table of Oil & Gas Fired Steam Boilers

| Type | Horizontal Steam Boiler | ||||||

| Model | WNS0.5- | WNS1- | WNS1.5- | WNS2- | WNS3- | WNS4- | |

| 0.4[0.7]-Y/Q | 0.4[0.7,1.25]-Y/Q | 1.0[1.25]-Y/Q | 0.4[1.25]-Y/Q | 0.4[1.25]-Y/Q | 0.4[1.25]-Y/Q | ||

| Rated | t/h | 0.5 | 1 | 1.5 | 2 | 3 | 4 |

| Evaporation | |||||||

| Rated | Mpa | 0.4/0.7 | 0.4/0.7/1.25 | 1.0/1.25 | |||

| Steam Pressure | |||||||

| Rated Steam Temperature | ℃ | 152/171 | 152/171/194 | 184/194 | |||

| Thermal Efficiency | % | 92% | |||||

| Diesel | Kg/h | 33.2 | 68.4 | 100 | 135 | 202 | 273.6 |

| Consumption | |||||||

| Natural Gas Consumption | Nm3/h | 37.5 | 76.6 | 114 | 151.2 | 230 | 308 |

| Coal Gas Consumption | Nm3/h | 92.1 | 184.2 | 245 | 328 | 490 | 650 |

| Power | V/Hz | 380/50 | |||||

| Voltage | |||||||

| Steam Outlet | mm | DN50 | DN80 | DN80 | DN80 | DN100 | DN100 |

| Water Inlet | mm | DN25 | DN25 | DN32 | DN32 | DN40 | DN50 |

| Drain | mm | DN40 | DN40 | DN40 | DN40 | DN50 | DN50 |

| Outlet | |||||||

| Chimney | mm | φ 200 | φ 300 | φ 350 | φ 350 | φ 400 | φ 450 |

| Length | mm | 2492 | 2850 | 3280 | 3922 | 4300 | 4980 |

| Width | mm | 1363 | 1600 | 2150 | 2260 | 2530 | 2430 |

| Height | mm | 1662 | 2000 | 2290 | 2300 | 2480 | 2740 |

| Weight | t | 1.95/2.5 | 4.4/5.2/5.8 | 7.6/8.0 | 8.28/9.48 | 9.26/10.3 | 16.6/17.04 |

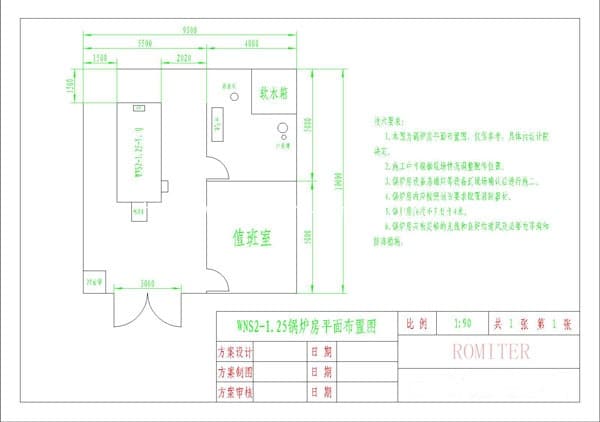

Layout Drawing of Oil & Gas Fired Steam Boiler

Company Profile

Romiter Group concentrating on supply high efficient and high intelligent boiler for customer. Main products include wood pellet hot water boilers, wood pellet steam boiler, wood pellet burner, coal fired thermal oil heater, diesel oil fired thermal oil heaters, biomass steam generator(wood dust, corncob, bagasse, rice husk, palm kernel shell), coal fired hot air generator, wood pellet hot air furnace, electric steam generator, coal fired steam generator, coal water slurry steam generator, diesel oil or gas steam generator, thermal oil steam generators, heat recovery steam generator (HRSG).